Oil-Water Separators

Oil-Water Separators (OWS) are used to recover and separate oil from water. Typically, the oil-water separation process allows for the oily water to sit undisturbed until oil globules begin to float. For years, American Petroleum Institute (API) separators have been the de facto solution for oil separation, but advances in technology and process design have introduced more cost-effective methods. FRC engineered its OWS design, the Corrugated Plate Interceptor (CPI), upon these technological advancements.

CPIs can be used in a variety of applications; from straightforward oil and gas oil-water separation to more complicated oil recovery in various food and beverage and general manufacturing applications. Some of the factors that go into designing an OWS range from the specific gravity of oil, size of oil droplets, temperature, salinity, and the consistency of the oil loading and hydraulic throughput.

Oil-Water Separator Features

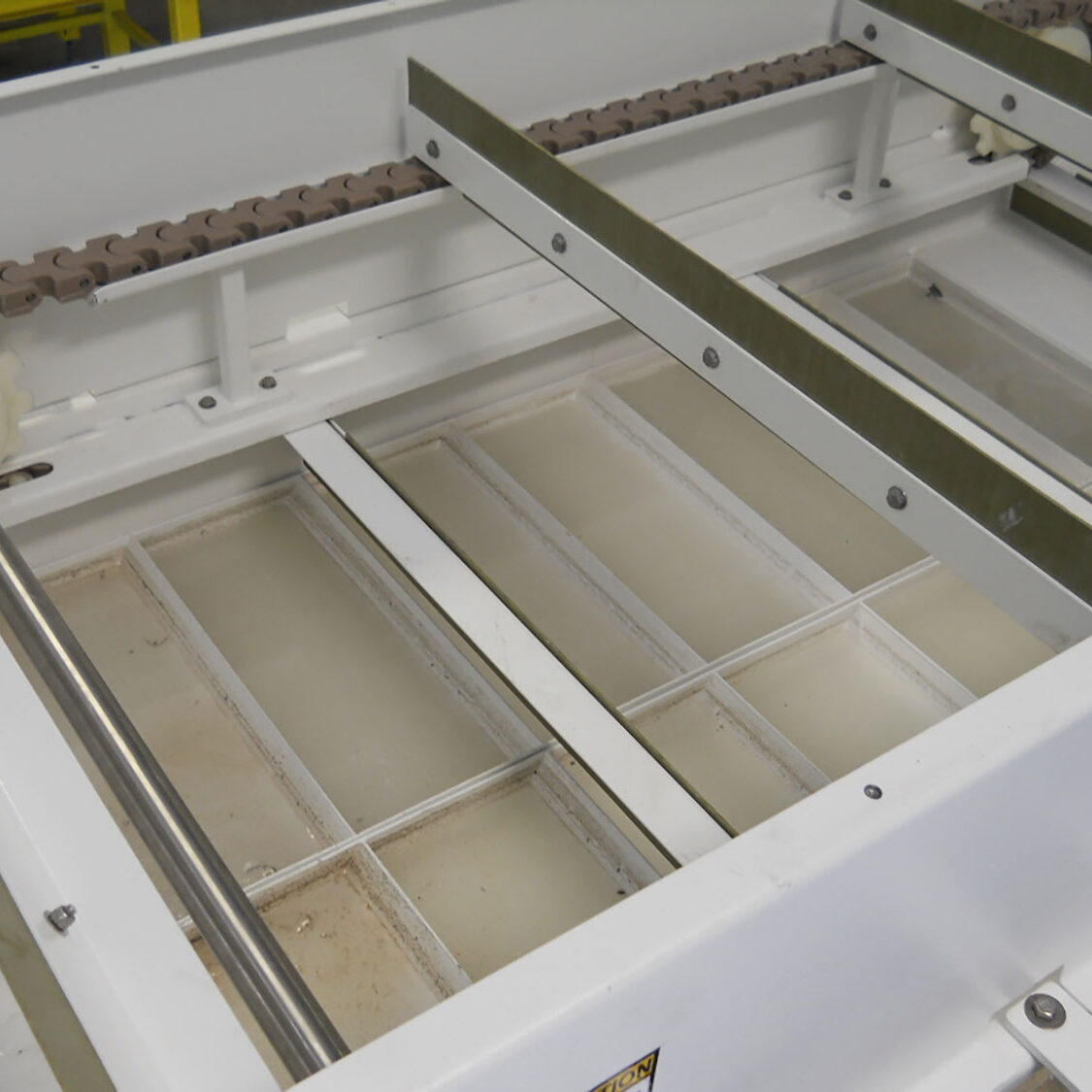

CPI Plate Packs/Compact Footprint

Inclined plate packs allow for influent wastewater to remain laminar while also lowering the footprint. The plate packs can be installed in either an above-ground CPI or as modules placed in a below-ground CPI.

Material of Construction

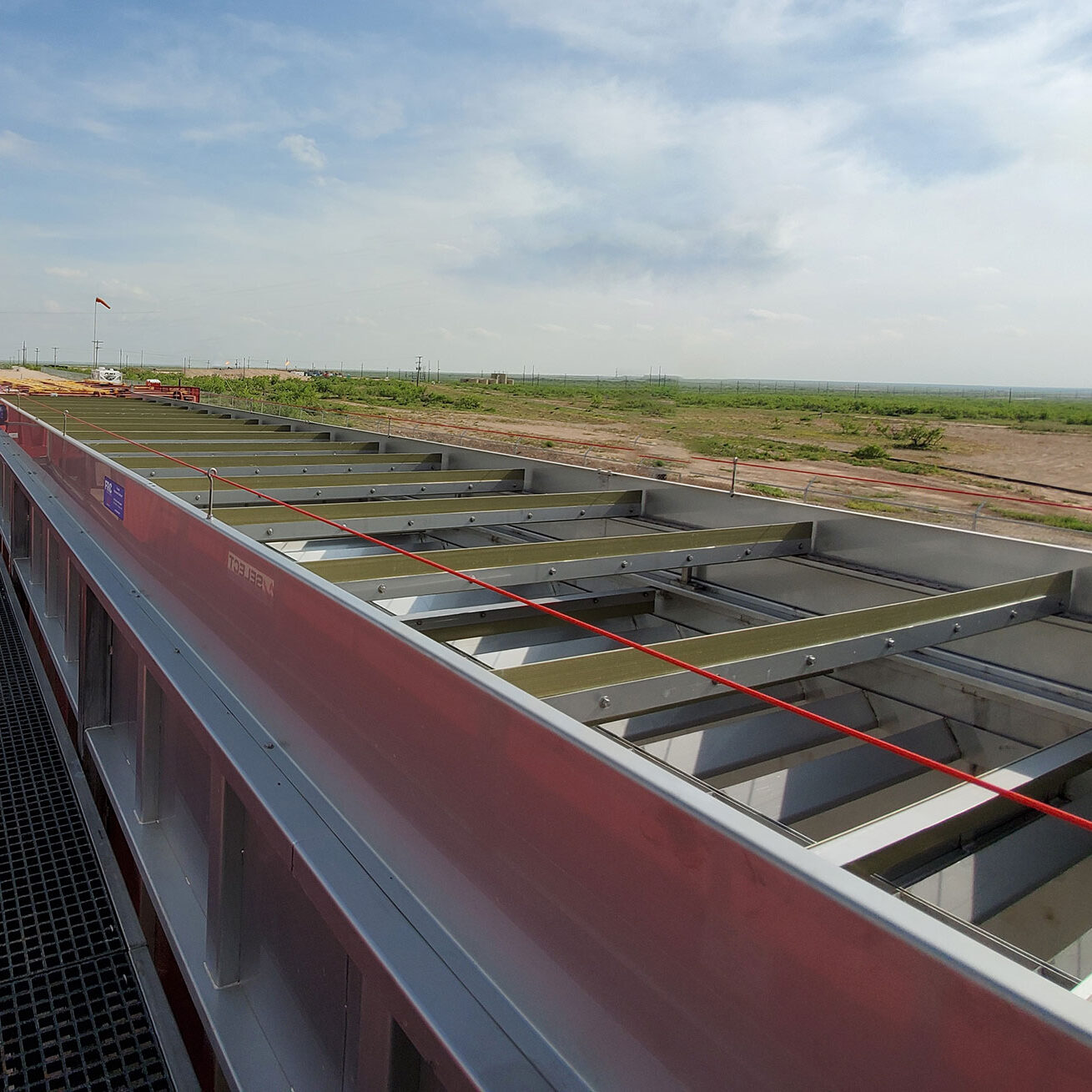

FRC above-ground CPIs are constructed using high-end stainless steel that’s resistant to corrosion, durable, and can be installed indoors or outdoors. Depending on the application, we can accommodate various alloys including stainless steel 316ti, duplex stainless steel, or carbon-coated steel.

Support Structures

FRCs CPI skid is constructed out of high-end stainless steel, which makes it just as durable and long-lasting as our CPI.

The CPI access catwalks are OSHA compliant and are constructed of stainless steel with FRP grating. They are completely customizable with stairs or ladders the shape required to accommodate your design and facility requirements.

Skimming System

FRCs CPIs use a top automated chain-and-flight skimmer which is beneficial in combatting the challenges in applications with high viscosity oil. The static skim pipe has no moving parts to minimize maintenance requirements.

Gas-Tight Cover

FRC gas-tight covers are engineered for applications that require complete segregation of the influent and atmosphere. The gas-tight covers are constructed of high-end stainless steel and come equipped with flange connections for sweeping gas such as nitrogen and dissolving gases. Other optional features include, plexi-glass access hatches, flame arrestors and vacuum relief valves.

API Large Free Area

The large free area of the API allows for the handling of high oil concentration as well as oil surges.

API Skimming Systems

FRCs API systems use a top automated chain-and-flight skimmer for combatting the challenges in applications with high viscosity oil along with a bottom automated chain-and-flight skimmer for the evacuation of settled solids.