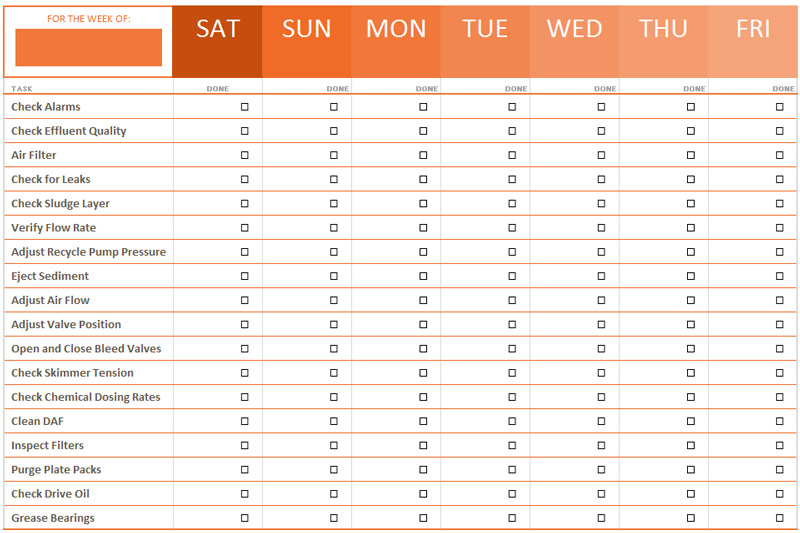

Like any other equipment in your facility, a DAF system absolutely must be maintained if you expect it to perform as designed. Whether you’re in charge of DAF system operation & maintenance or you’re in charge of the guys whose job it is to maintain the DAF system, here’s the list of maintenance procedures that should be performed on a daily, weekly, and monthly basis.

Daily:

- Check all control system alarms

- Monitor effluent quality/turbidity

- Clean air filter/regulator in pneumatic panel

- Inspect system for leaks in pipes and pumps

- Adjust water level to generate thick sludge layer

- Monitor influent flow rate

- Check and set recycle pump pressure

- Eject sediment from drain valves

- Check and set air flow setting in pneumatic panel

- Check for clogging in aeration valves

- Open and reset all bleed-off valves to clear obstructions

- Monitor skimmer system for smooth operation and correct tension

- Check and set chemical dosing rates (if chemically equipped)

- Inspect chemical supply (if equipped)

Weekly:

- Drain and clean DAF unit

- Inspect strainers and filters. Replace as necessary

- Purge plate pack using purge valves

- Inspect and clear tanks and sumps of sediment

Monthly:

- Apply anti-seize to frequently-used threaded parts

- Grease all bearings

- Check skimmer/auger drive oil

- Check recycle pump oil/grease (if equipped)

- Inspect 3rd party components as per their O&M Manuals

- Check lamps on control panel

- Switch to alternate pumps/motors

Do these simple tasks and you should be able to keep the system working like a charm. If for some reason something’s not working or needs replacement, give us a call. We stock all DAF System spare parts for immediate shipment.