Open-Style DAF

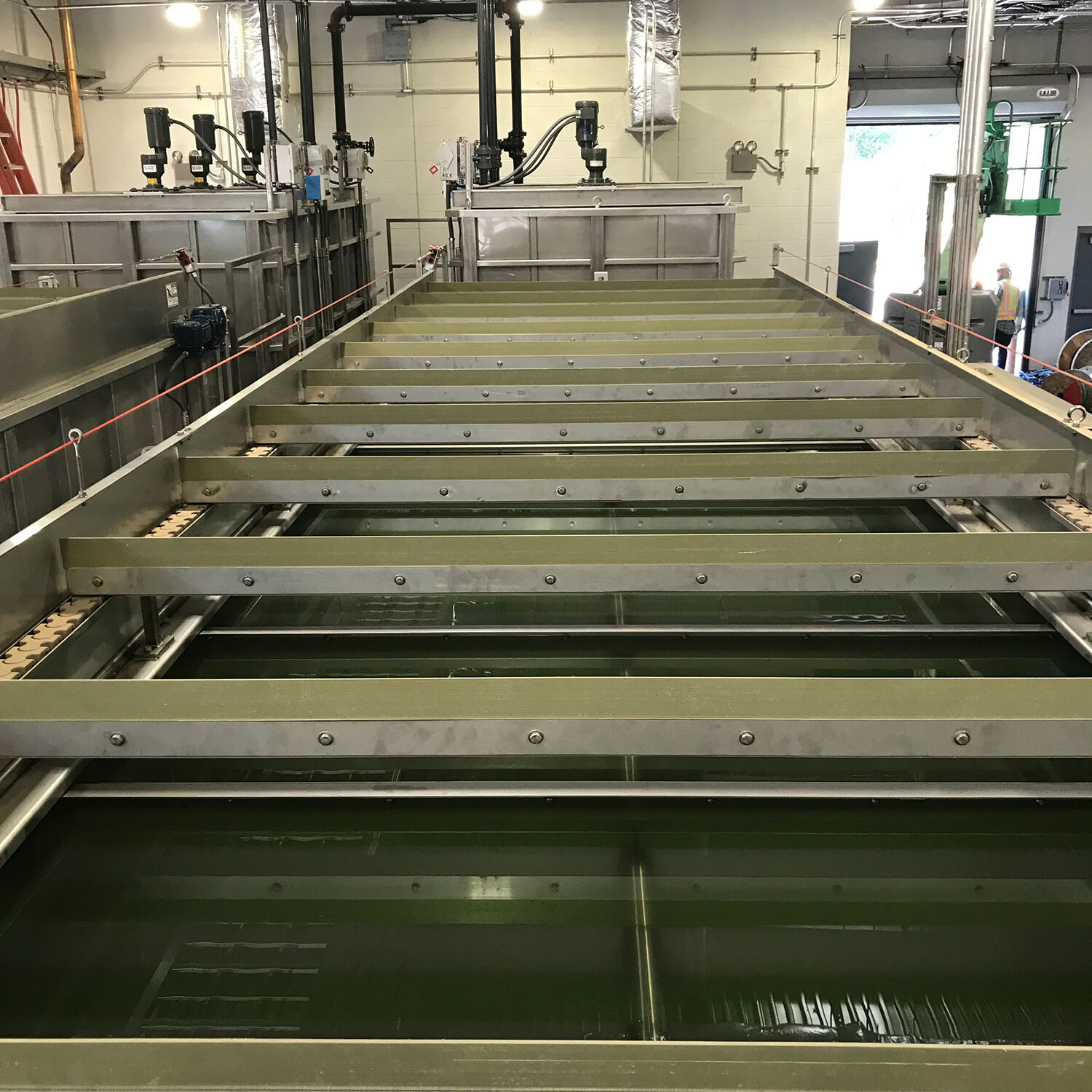

The FRC PWL series dissolved air flotation (DAF) system is an open tank, low-built design optimized for treating wastewater heavily loaded with solids. The PWL DAF provides the large amount of free surface area required for flotation and separation in these applications.

DAF systems can be used to effectively remove Total Suspended Solids (TSS), Fats, Oils, and Grease (FOG), Biological Oxygen Demand (BOD), Chemical Oxygen demand (COD), and other pollutants from wastewater. Open style units are particularly proficient for high solids concentration and can be built wider and longer as the free separation area requirement increases.

FRC has been engineering wastewater treatment systems for almost half a century and has the experience to design the optimum solution for your needs.

PWL Series DAF Features

Material of construction

When you invest in a DAF system, you want something that is going to hold up in a harsh environment. FRC constructs our DAF using high-end stainless steel. Stainless steel resists rust and retains its strength between temperatures of -320°F to 1,500°F ( -196° to 816° C), so it holds up in both indoor and outdoor applications. Even after decades of use, stainless steel tanks can be retrofitted and continue to work for decades longer because the steel structure remains sound.

Support Structures

Just like our DAF, all FRC skids and catwalks are constructed out of high-end stainless steel so they will be equally durable and long-lasting.

Our access catwalks are OSHA compliant and completely customizable and can be designed with stairs or ladders in a variety of different shapes to accommodate your design and facility requirements. Depending on the application, we can accommodate various alloys including Stainless Steel 316ti and Duplex Stainless Steel.

Aeration System

FRC takes an engineered approach with our aeration system. Our centrifugal recirculation pumps are used for just that – recirculating water. They’re readily available from any pump vendor, have a high tolerance for solids, can be made of extremely hard materials, and are less expensive to own and operate than specialty whitewater pumps.

By placing the responsibility for generating whitewater on a static tube made of stainless steel, the centrifugal pump can focus on what it does best – move water.

The whitewater is generated in a static “air dissolving tube” downstream from the pump as water comes in contact with small volumes of compressed air. This design aspect allows for almost instant saturation by creating higher interface between the clarified effluent and the compressed air.

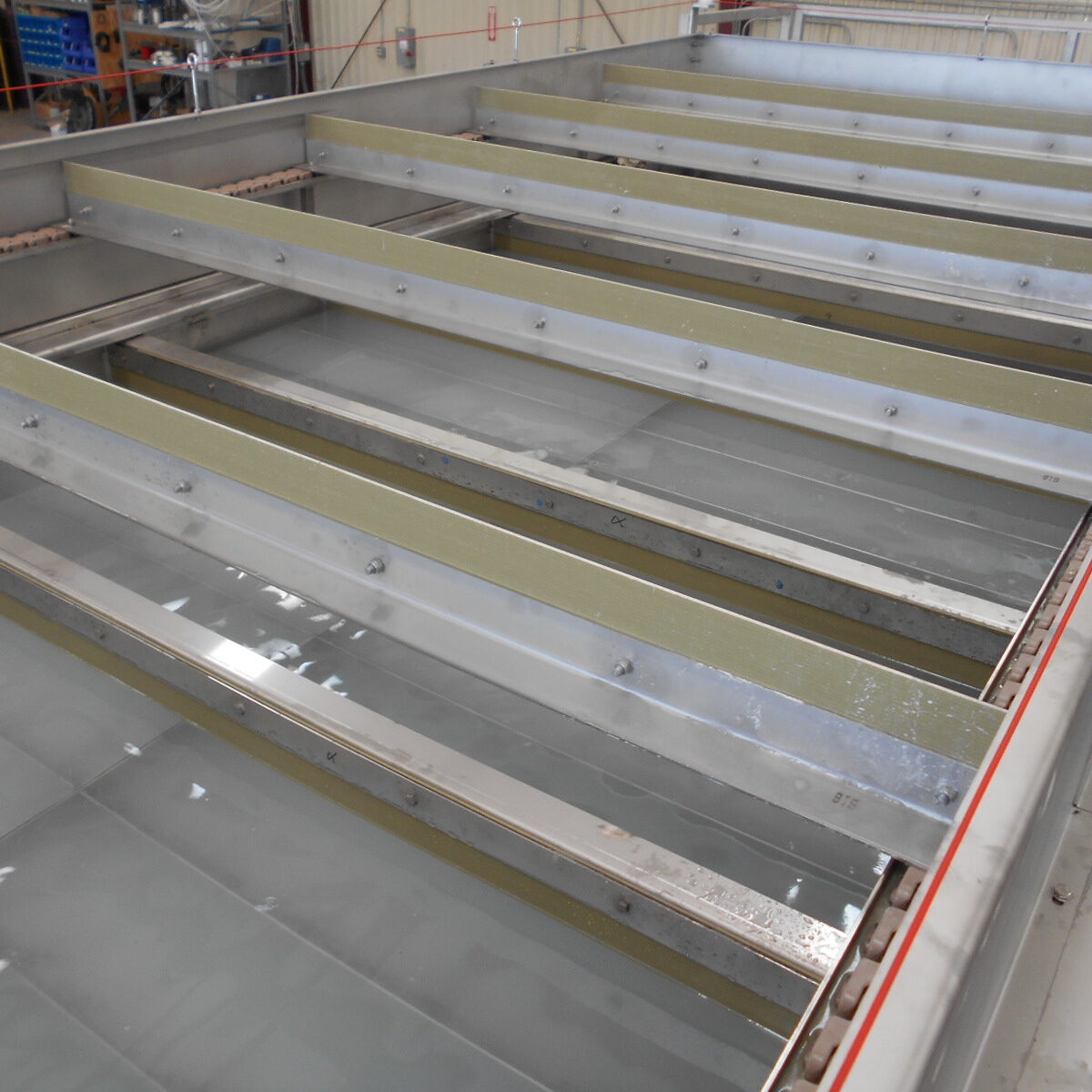

Dewatering Grid

The sludge dewatering grid helps operators control sludge thickness, eliminates pre-mature removal of solids, reduces build-up and/or re-entrainment of sludge, and ultimately generates drier sludge.

Drier sludge means less required storage capacity, less dewatering equipment, and less chemical expenses on re-processing filtrate water (the water that separates out of sludge after dewatering) through the DAF system. You have everything to gain by going with a DAF system that’s engineered to produce drier sludge.

Open Flotation Cell & Counter-Current Skimmer

In PWL DAF systems, wastewater is introduced into the DAF tank and processed in a flow-through manner – wastewater comes in one side and goes out the other. While many DAF system designs push sludge across the entire length of the tank in the same direction as the wastewater flow, FRC’s PWL design uses a skimmer assembly that rotates against the hydraulic flow of the water. This design shortens sludge skimming distance and eliminates solids carry-over.

Gas-Tight Cover

FRC can provide a custom engineered stainless-steel gas-tight cover for your open-style DAF if your application requires complete segregation of the influent and atmosphere. The gas-tight covers are designed with flange connections for sweeping gas such as nitrogen and dissolving gases. Plexi-glass access hatches, flame arrestors and vacuum relief valves are also available as options.