A popular salad dressing and dips company was out of compliance with unmonitored effluent and only had manual testing in place.

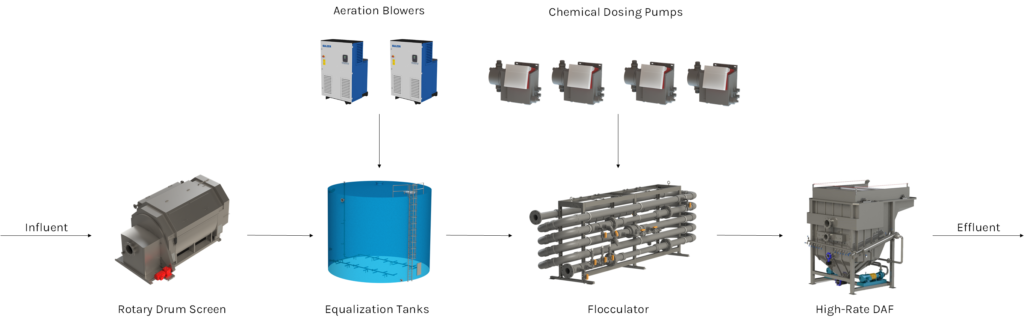

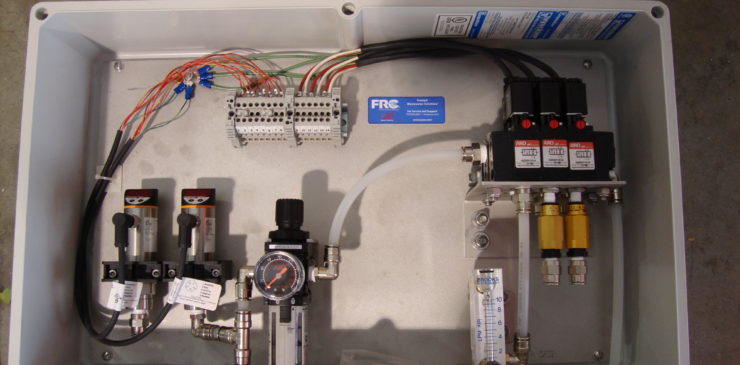

FRC conducted a detailed site survey to determine how to bring the client back into compliance and improve process reliability. The DAF had whitewater recycle pumps that had been damaged due to air being introduced to the pump suction causing increased wear-and-tear. This resulted in an ineffective DAF whitewater aeration system. In additionally, the influent wastewater had inconsistent flow rates and fluctuating pH levels due to the underutilization of the equalization tanks. The chemical dosing equipment was controlled manually which requires a high amount of operation intervention. Lastly, the control panel had minimal/insufficient programming of the PLC & HMI as well as damaged and malfunctioning instrumentation.

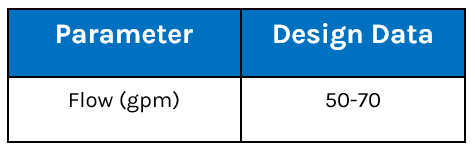

FRC came up with a turnkey (electrical & mechanical) solution to upgrade the existing wastewater treatment system and bring them back into compliance. Our upgrades included an aeration upgrade to DAF, flocculator modifications, a complete control panel upgrade, and new instrumentation, valves, and chemical dosing systems.