High-Rate DAF

FRC PCL & PCCS series high-rate Dissolved Air Flotation (DAF) design provides an efficient and cost-effective solution for removing Total Suspended Solids (TSS), Fats, Oils, and Grease (FOG), and other pollutants from your wastewater.

On the surface the DAF process is straightforward – tiny bubbles attach to solid contaminants causing them to float. The sludge is then skimmed off the surface of the water. Designing a DAF system for a real-world application is a little more complicated. FRC’s highly skilled engineering team looks at the specific requirements of your application and creates the best solution specifically for your unique needs.

With hundreds of DAF installations, FRC has the experience to select the correct high-rate DAF for your application.

FRC PCL/PCCS DAF Features

Corrugated Plate Packs

Inclined plate packs allow for influent wastewater to remain laminar. The plate packs improve the overall system performance by increasing the effective separation area of the DAF, thereby decreasing the hydraulic surface loading rate. This design allows for tanks with a significantly reduced footprint, saving valuable space in your wastewater treatment facility.

Aeration System

FRC uses an air dissolving tube to generate whitewater in our aeration system. The reasoning is simple. Air will never be introduced to a pump. This short expansion in the recirculation piping allows clarified effluent and a small volume of compressed air to mix until the air dissolves into the water. Our angled configuration allows for increased water and air interface, so saturation occurs almost instantly.

FRC’s design uses a standard centrifugal pump to recycle water, not dissolve air. Recycle pumps provide a more efficient and cost-effective system than expensive whitewater pumps by providing higher solids tolerances, using more durable pump materials, and operating at lower pressures.

Dewatering Grid

The dewatering grid is a rectangular framework of angular steel plates that locks sludge in place as it rises to the surface. By holding the sludge in place, it allows for additional drying of the solids before being skimmed, reducing sludge disposal cost. The dewatering grid also eliminates the pre-mature migration of solids as well as eliminating re-entrainment of solids back into the DAF.

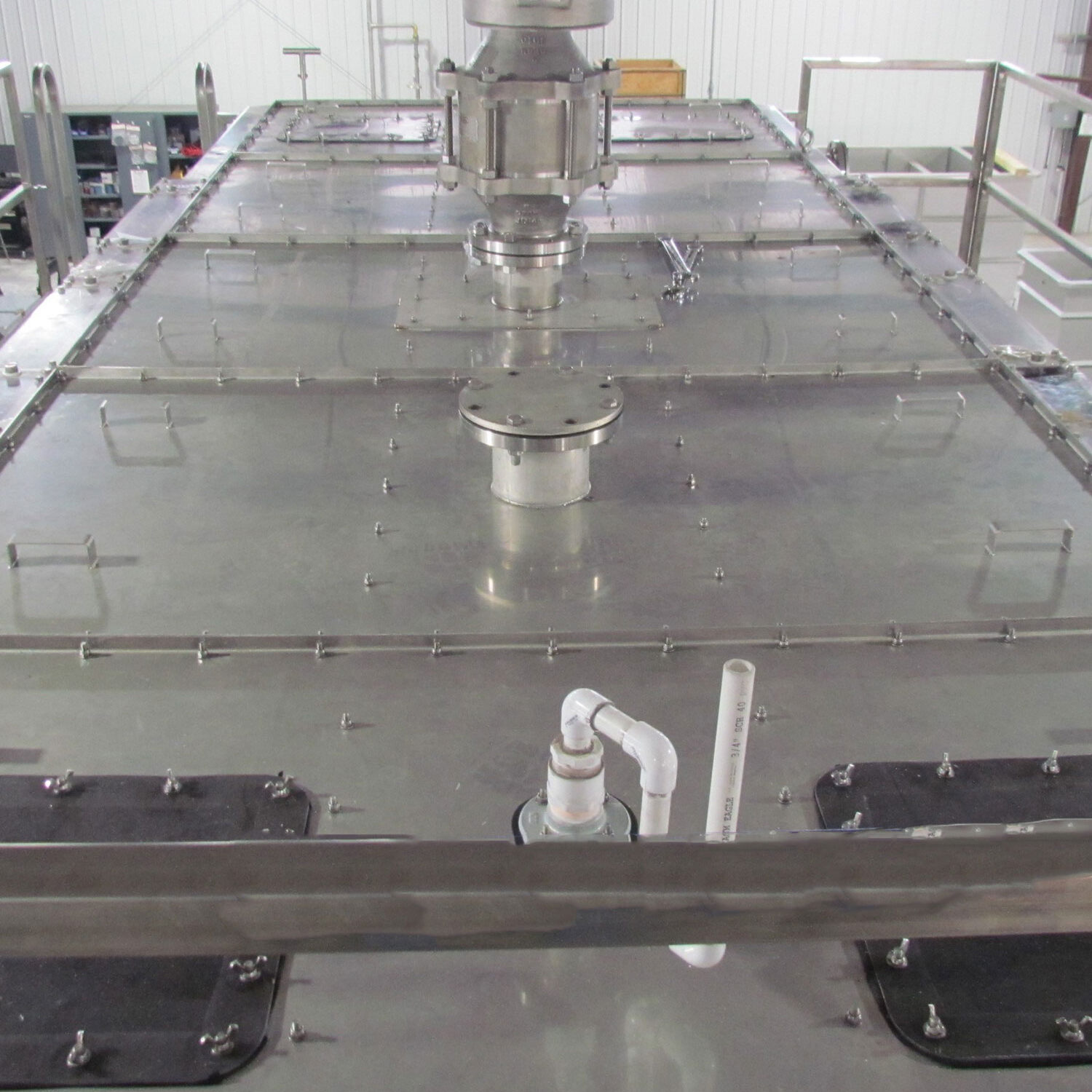

Material of construction

FRC constructs our DAF units using high-end stainless steel, which is resistant to corrosion, can be installed indoors or outdoors, and is extremely durable and long-lasting. Depending on the application, we can accommodate various alloys including Stainless Steel 316ti and Duplex Stainless Steel.

Support Structures

FRCs DAF skid is constructed out of high-end stainless steel, which makes it just as durable and long-lasting as our DAFs.

Our access catwalks are OSHA compliant and are constructed of stainless steel with FRP grating. They are completely customizable with options for stairs or ladders in a variety of different shapes to accommodate your design and facility requirements.

Gas-Tight Cover

When your application requires complete segregation of the influent and atmosphere, FRC can provide a custom engineered stainless steel gas-tight cover. The gas-tight covers come equipped with flange connections for sweeping gas such as nitrogen and dissolving gases. Plexi-glass access hatches, flame arrestors and vacuum relief valves are also available as options.

Compact Footprint

FRC’s PCCS DAF Systems are ideal for ocean shipping. These systems are designed to fit inside standard 20’ ISO shipping containers, allowing for standard rate shipping costs.